Air quality

GRI 305-7Our environmental programmes are being implemented as a matter of priority. As a result of our efforts, the project team has grown in capability. We have refined our approach to air quality in the light of both specified environmental targets and long-term environmental impacts. The level of control by the Group’s management was raised as well in 2021. We believe that these improvements in our approach will lead to concrete results as we keep adapting our strategy to become more integrated, considering the interconnected nature of the environment, our employees’ health, and the wellness of the communities in which we operate.

As part of its business operations, EVRAZ acknowledges that it generates a significant amount of air pollutants, with the potential to have adverse consequences for the environment as well as human health. Pollutant emissions are unavoidable throughout the steelmaking process. Carbon monoxide (CO), sulphur oxides (SOx), nitrogen oxides (NOx), particulate matter (dust), and volatile organic compounds (VOCs) are the key pollutants released during steel manufacturing (VOCs). Fuel combustion is the primary source of carbon dioxide and nitrogen oxides. During the blast furnace manufacturing process, large amounts of carbon monoxide are also produced. Oxidation of sulphur in ore or coking coal releases sulphide oxides as an exhaust gas component. Coal mining produces dust mostly during the transportation and storage of coal but also at all phases of metallurgical processing (sintering, blast furnace, steelmaking, rolling production). Coke manufacture is the primary source of volatile organic compounds.

DUST EMISSIONS

In our operations, we implement the most cutting-edge technology and keep our equipment up to date on a regular basis while also closely monitoring all emissions for any violations of permitted limits. Our Environmental strategy includes air emission reduction goals, which call for a 33 % decrease in steel manufacturing emissions and a 1,5-fold reduction in dust emissions during coal transportation and storing.

CWP Raspadskaya was equipped with

The unit is autonomous and mobile. The range of its fog jet is up to 90 meters, the coverage of one unit is up to 24, 000 square metres. The water “cannon” rotates by 320 degrees.

Dust suppression programme in coal storages

| RUK COMPANY | NUMBER OF DUST SUPPRESSION UNITS | ||

|---|---|---|---|

| 2020 | 2021 | TOTAL | |

| WP Raspadskaya | 1 | 1 | 2 |

| Raspadskaya Koksovaya | |||

| CWP Abashevskaya | 1 | 1 | |

| CWP Kuznetskaya | |||

| Mine "Alardinskaya" | |||

| Mine "Osinniskaya" | |||

| Mine "Uskovskaya" | |||

| TOTAL | 1 | 2 | 3 |

In 2021, we carried out additional activities to reduce dust emissions such as watering of roads, also with reagents, covering coal carrying trucks with sheets.

Key air emissions

Sulfur oxide (SOx), nitrogen oxide (NOx), volatile organic compounds (VOCs), and particulate matter (dust) are among our key emissions. In 2021, total air emissions from steel production decreased by 2.9% against the 2020 level due to the reduction in production at ZSMK and re-equipment of gas cleaning facilities at KGOK.

A wide range of actions and investments are being carried out by EVRAZ in order to achieve the environmental strategy objectives. These include activities and investments carried out under the framework of the Clean Air project, part of the Ecology national project in Russia. As part of the execution of the Clean Air federal initiative, EVRAZ is taking considerable steps to increase the efficiency of its gas treatment facilities.

As of the end of 2021, EVRAZ ZSMK had decreased its total emissions by 16,900 tonnes. To reduce emissions of sulphur dioxide (SO2) and specific coke production, EVRAZ ZSMK plans to implement the following measures in 2021–2024:

- Constructing a modern facility for flue gas desulphurisation at the sintering plant, which will contribute to a 58% reduction in emissions of key pollutants for Novokuznetsk by 2024.

- Decommissioning the cooling tower for the final cooling of coke gas at the coking plant, which will reduce emissions in hazard classes 1 and 2 from coke production by 76%.

EVRAZ NTMK is also involved in the Clean Air project. The initiatives that it has implemented have made it possible to reduce emissions by 7,400 tonnes. To reduce emissions of harmful pollutants and address public concerns, the following measures are planned for 2021–2024:

- Decommissioning the cooling tower for the final cooling of the coke gas at the coking plant.

- Constructing a new biochemical facility at the coking plant.

- Introducing new technology for pitch production (replacing old equipment).

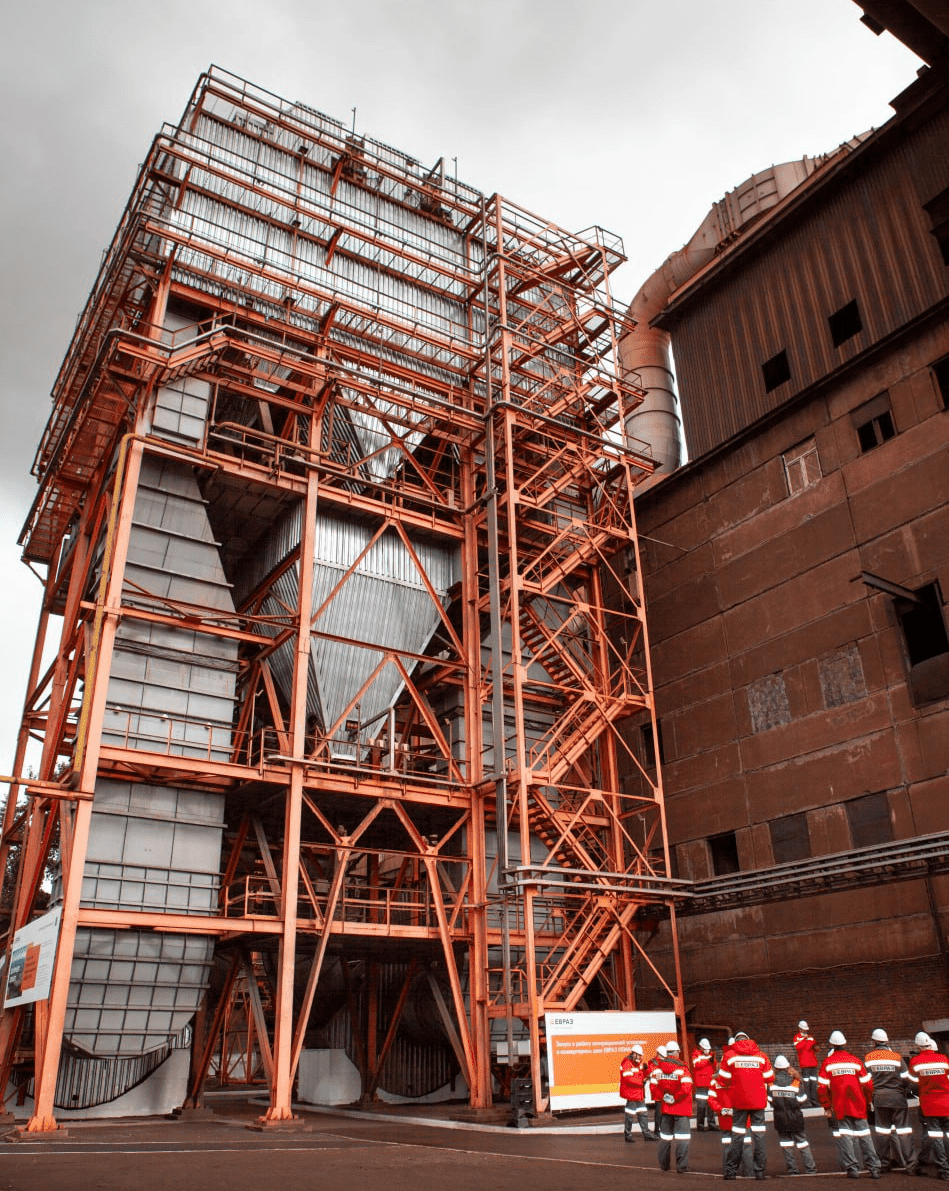

Following commissioning at EVRAZ NTMK, a large aspiration unit was installed in the converter shop’s mixing compartment. This is one of the enterprise’s most significant measures within the Clean Air federal programme.

US$5.3 million was invested in the project by EVRAZ. The new system will capture at least 95% of the iron overflow emissions in the mixing compartment, resulting in a reduction of more than 32 tonnes of particulate matter (dust) per year. The aspiration system consists of two exhausters and energy efficient motors, over 200 filters and sealed receiving bins. The equipment removes fine particles from approximately 1 million cubic metres of air per hour. The dust is collected and used to make iron flux, which is added throughout the iron manufacturing process. When contaminated air with a dust content of 2 g/m3 enters the aspiration unit, a residual dust concentration of no more than 0.02 g/m3 is achieved.

In 2021, the EVRAZ KGOK agglomeration plant overhauled the electrostatic precipitators of sintering machine No. 1 and calcining machine No. 4. We modernised the aspiration of the housing for the loading bins of the agglomeration shop. As a result, emissions decreased by 1,300 tonnes. In 2022, our work on the modernisation of dust and gas cleaning equipment will continue. Also, EVRAZ KGOK performed an audit of the quarry treatment facilities, installed a modern system for the collection and disposal of quarry water at the new Sobstvenno-Kachkanarskoye field, and strengthened the existing tailings dams. During the summer, EVRAZ KGOK carried out dust suppression activities at the tailings and open pits.